Wooden Fence Installation

Download the PDF or read through our step-by-step installation instructions to build your wooden fence.

ITEMS YOU WILL NEED

| Tools | Materials |

| Power saw | String |

| Hammer | Grade stakes |

| Level | Concrete and gravel |

| Posthole digger | Fence panels or pickets |

| Power drill | Fence posts |

| Tape measure | 2x4s for bracing posts |

| Carpenter’s pencil | Nails or screws* |

* Use hot-dip galvanized fasteners or other fasteners as required by building codes

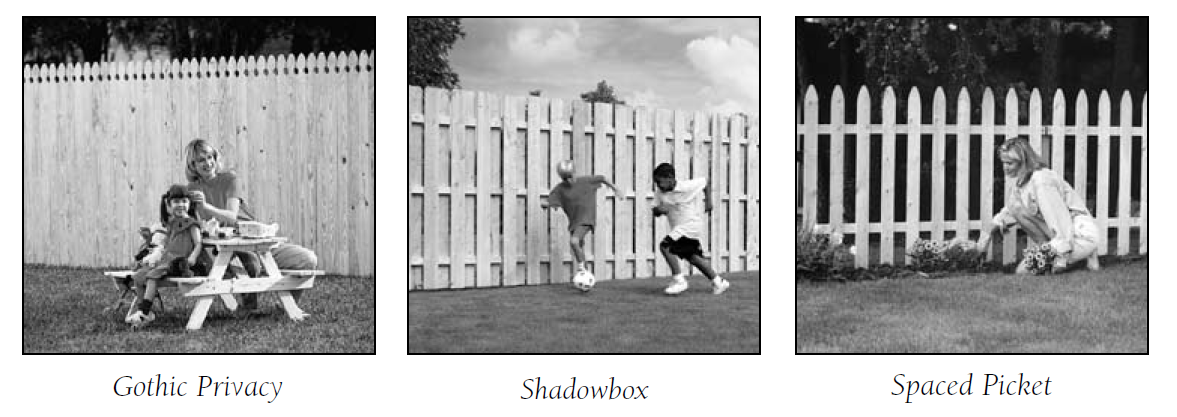

Choose Your Fence Style

Whether installing preassembled panels or building with components, there is a fence style right for you. Preassembled panels make installation easier and are perfect for long runs. Components leave you with more flexibility on short runs (less than 8’) and on sites that are not level.

Create your own look with:

- Solid – Allows for complete privacy. Used to surround swimming pools, define property lines or cover unattractive areas. (See Gothic Privacy photo below.)

- Spaced Picket – Ideal for defining boundaries while maintaining decorative appeal. (See Spaced Picket photo below.)

- Shadowbox – The ideal “good neighbor” fence features the same look on both sides. This style has the look of a privacy panel but allows for more air circulation. (See Shadowbox photo below.)

Preparation for Installing Wood Fences

Check with local ordinances and regulations before building fences in your area. Before construction, contact your local utility companies to mark any underground cables and pipelines. In addition, it’s a good idea to discuss plans with any neighbors along your proposed fence line.

Design and Layout

- Determine the number of posts, panels and gates needed to complete the job based on total linear footage. Take into consideration post, panel and gate width when determining the total number of each.

- Adjust layout to accommodate as many full panels as possible. If you must use part of a panel, place in the farthest rear corner of the property. Some types of pre-assembled panels can be trimmed to fit odd-sized layouts, but other types are difficult or impossible to cut to size.

- Locate property boundaries and drive stakes into the ground at corners and ends of fence line, 6” inside property boundary.

- Stretch twine or heavy string between stakes and pull tight to mark layout of fence line.

- Be sure to measure your fence panels and gates prior to locating the postholes. Also take into consideration your chosen method of attaching the backer rails to posts (see Connecting Backer Rails to Posts section). Locate post placement in the following order along string line.

- End/corner posts

- Gate posts

- Line posts

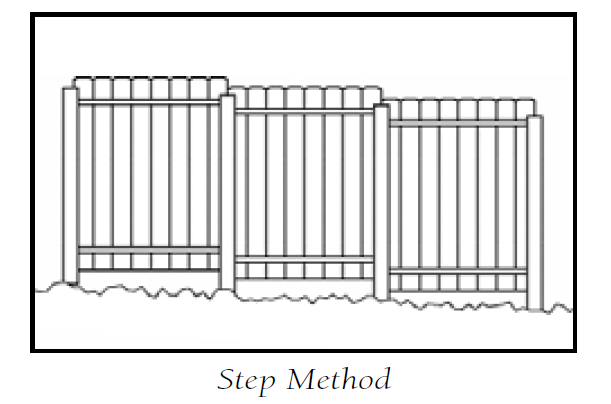

Installing Fences on Sloped Landscapes

Fences are installed on slopes using one of two methods (see Fig. 1). Pre-assembled panels can only be installed using the step method. The fence gradually steps up the slope with the rails level, rather than parallel to the slope. With loose components, you have the option to use the parallel method. The rails are installed based on the degree of the slope. Since this method requires that the fence be constructed to conform to the slope, it cannot be accomplished using pre-assembled fence panels.

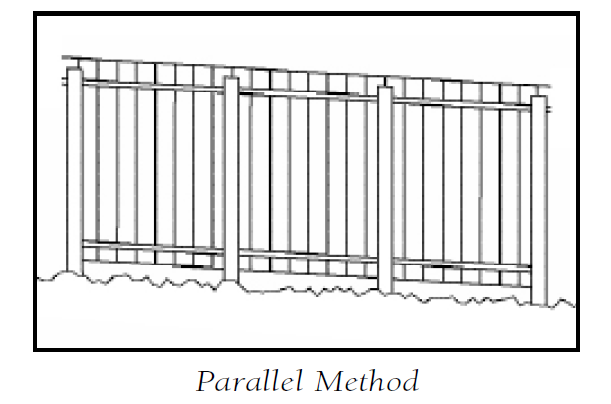

Digging Post holes

Fig. #1

A general rule of thumb is to place 1/3 of the length of the post in the ground. The fence will be stronger if end, corner and gate posts are set at least 6” deeper. Using a post hole digger or power auger, dig the holes 10-12” wide and 6” deeper than needed. Back-fill the hole with 6” of gravel to drain water away from the bottom of the post (see Fig. 2). Keep the height of your fence panels in mind when digging your post holes.

Setting Posts

Install end and corner posts first. Tie a string between the posts along the fence line. This establishes a reference, ensuring the posts are in line (see Fig. 3).

Brace the posts using 2x4s nailed to both the posts and stakes in the ground. This will keep them straight while the concrete sets. Check for plumb (90º angle) on two adjacent sides prior to pouring concrete. Fill holes with ready-mix concrete following the package instructions. Tamp the concrete to remove any air pockets. Overfill the holes at the top and slope the concrete away from the post to keep water from collecting around it. Recheck plumb and alignment of all posts and allow concrete to cure for 24 to 48 hours.

Cutting Posts to the Proper Height

An easy method to ensure your post tops are level is to run a string from corner post to corner post at the desired height, keeping the string taut (see Fig. 3). Mark each post at the string line and cut off the tops of the posts. Finish off your posts with one of our decorative finial tops.

Installing Wooden Fence Panels and Pickets

For preassembled fence panels, use 18d to 20d nails to attach them to the posts. If possible, pre-drill holes through the panels to minimize any splitting from using such a large nail.

To install loose pickets to backer rails, use 8d or 10d box nails. Start at one end of the rail and check for level and plumb every three or four pickets. If you wish to build a solid “privacy” fence, butt the pickets without leaving a gap in between. To build a spaced picket fence, cut a board the width of the desired gap and use it as a spacer. Remember to check for plumb every few pickets. Use two backer rails for shorter fences, three rails for fences 6’ tall, and four rails for 8’ tall fences. Backer rails should be attached on edge to prevent sagging.

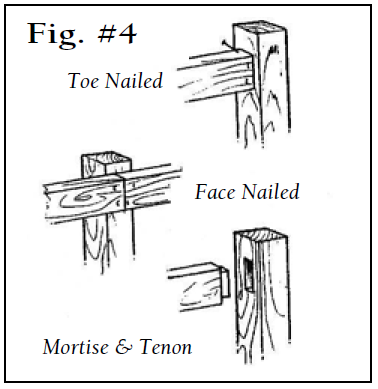

Connecting Backer Rails to Fence Posts

There are many ways to attach the backer rails or stringers to the posts (see Fig. 4). Place a board under pre-assembled panel to use as a lever to adjust the panel to the proper height on the post. All backer rails should run the same measurement to the ground and to each other on a horizontal plane, regardless of minor grade changes. Your finished product will be much more appealing to the eye if proper attention is given to this detail.

Gate Installation

- Determine the swing direction of the gate (left or right-hand open).

- Mount hinge hardware to gate frame at the proper height, pre-drilling all screw holes.

- Mount gate to gate post, pre-drilling all screw holes.

- Check for full gate swing clearance.

- Mount latch hardware, pre-drilling all screw holes.

Finishing Your Fence

Applying a protective finish is recommended to prolong the life of your fence. The type of finish will be determined by the look desired, as well as the species of wood used. There are three options in finishing treatments: stain, paint and waterproofing sealer. Clean your fence with a cleaner/brightener that contains a mildewcide, prior to applying your finish.

- Stain provides a durable finish coat while maintaining the natural look of wood. A semitransparent stain is recommended for new fences; it gives an even appearance and hint of color

while allowing the grain to show through. - Paint adds color as it protects and seals the fence. The color can easily be coordinated with your home. Clean, dry and prime with oil-based primer prior to painting the fence. A durable exterior latex paint is recommended.

- Waterproofing sealer is best for woods that are not naturally resistant to decay and exposure to weather. The sealer helps prevent rain and moisture from soaking into the wood. Add a UV stabilizer to slow the discoloration process.

Care and Maintenance

- The continuous changes in weather conditions are hard on your fence. Your maintenance plan must be geared to combating the problems caused by water absorption and loss, mildew growth, and UV discoloration.

- First-year maintenance – Reapply cleaner/brightener as described in initial maintenance, as well as your method of finish (paint, stain or water sealer). This should be completed after 12 months.

- Future periodic preventative maintenance – Depending on the location of your fence with regard to direct sun exposure, foliage coverage, etc., it may be sufficient to clean/ brighten and recoat every two years. A power washer may be necessary to properly clean your fence.

The diagrams and instructions in this brochure are for illustrative purposes only, and are not meant to replace a licensed professional. Any construction or use of the product must be in accordance with all local zoning and/or building codes. The consumer assumes all risks and liability associated with the construction or use of this product. The consumer or contractor should take all necessary steps to ensure the safety of everyone involved in the project, including, but not limited to, wearing the appropriate safety equipment. Universal Forest Products, Inc., makes no warranty, either express or implied, and shall not be liable for any damages, including consequential damages.